Why smarter visibility is the missing link in stopping supply chain loss

Shrinkage—whether due to theft, spoilage, miscounts, or misroutes- is one of the silent killers in the FMCG sector. For food brands, where margins are already thin and shelf lives are short, these “invisible losses” can compound quickly, eating into profits and eroding trust across the supply chain.

Traditional loss prevention strategies focus heavily on audits, after-the-fact reporting, or siloed inventory checks. By the time discrepancies are found, the damage is done. The smarter, more proactive approach? Real-time visibility.

The Shrinkage Problem in FMCG

According to industry benchmarks, shrinkage accounts for up to 2–3% of annual revenue in retail and FMCG. In food supply chains, losses also come from:

- Expired or spoiled goods due to delays or poor rotation

- Stock misplacements in fragmented distribution networks

- Theft (internal or external) across warehousing or retail points

- Errors in manual stock entry or tracking

In high-velocity environments, these losses aren’t isolated; they’re systemic. And because they’re often hidden across multiple layers (supplier, warehouse, transit, retail), they require systemic visibility to uncover and address.

Visibility Isn’t Just Good to Have—It’s Mission-Critical

Real-time visibility provides transparency across every node of the supply chain, allowing teams to detect anomalies the moment they occur, not weeks or months later.

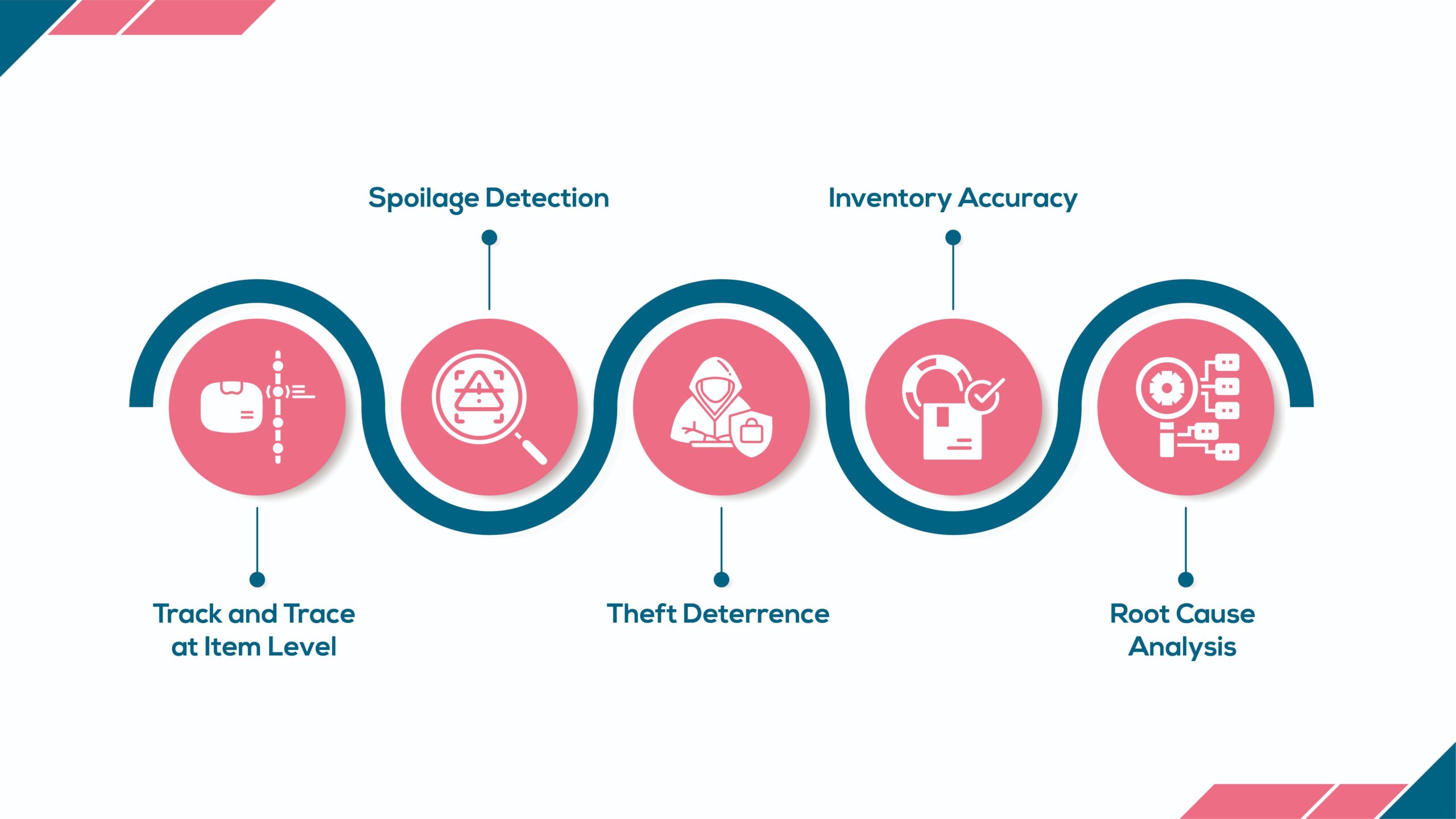

Here’s what it enables:

- Track and Trace at Item Level: Follow each unit from supplier to shelf.

- Spoilage Detection: Monitor temperature, time, and transit conditions.

- Theft Deterrence: Use geo-fencing and unauthorized movement alerts.

- Inventory Accuracy: Match expected vs actual inventory in real-time.

- Root Cause Analysis: Identify patterns of loss across specific lanes or SKUs.

In essence, real-time visibility helps you track, trace, and stop disruptions before they impact customer experience or profitability.

How Farm To Plate Powers Real-Time Shrinkage Control

At Farm To Plate, we’ve built a visibility-first platform that empowers FMCG brands to fight shrinkage at its source, with clarity, speed, and precision. Whether it’s tracking fresh produce from farm to shelf or reducing spoilage in transit, our system delivers end-to-end control through:

- Item-level tracking with RFID & IoT

- Live dashboards integrated with your ERP/WMS

- Automated loss detection and alerting

- Route-level visibility across suppliers, warehouses, and retailers

Our customers benefit from real-time transparency that turns guesswork into insight and insight into decisive action. From raw material intake to last-mile delivery, shrinkage has nowhere to hide.

With Farm To Plate, you don’t just detect losses, you prevent them.

What the Market Is Saying

Leading retailers and manufacturers are ramping up investment in real-time visibility tools. Gartner predicts that by 2026, over 75% of FMCG brands will have adopted real-time inventory monitoring, up from just 25% in 2022.

Why the surge?

- Higher consumer expectations around freshness, availability, and trust

- Tighter regulations on traceability and food safety

- Mounting pressure to reduce food waste and carbon footprint

- A shift from reactive to proactive loss prevention

The message is clear: you can’t manage what you can’t see, and today’s supply chains demand total visibility.

Final Thought: See More, Lose Less

FMCG brands can no longer afford to treat shrinkage as a sunk cost. In a world of instant deliveries, fresh guarantees, and thin margins, every lost unit matters.

Real-time visibility isn’t just about better control—it’s about building a resilient, intelligent, and profitable supply chain. The kind that detects losses early, solves problems faster and never flies blind.

Track it. Stop it. Grow from it.

Written by Sravya Priya, Content Specialist at Farm to Plate. She simplifies complex tech and writes about AI in supply chains, product innovation, and the future of food tech.