It started with one spoiled shipment. Just one. The order was packed correctly, on time, and at the correct temperature. But the demand curve spiked early that week, and by the time the product hit the shelf, it was already obsolete. Or worse, expired.

No one saw it coming. Because the forecast was based on last year, that single misstep cost the supplier their buyer. A long-standing contract, gone.

And this isn’t a one-off story — it’s what happens every single day in 2025’s F&B world.

Why does this matter now?

Because everything has changed, before COVID, your forecasts could afford to be fuzzy. After COVID, the cracks showed. And in 2025?

- Consumers demand fresher. Faster. Verified.

- Markets shift weekly, not quarterly.

- And “I think we have enough” just doesn’t cut it anymore.

Inventory used to be your safety net.

Now, it’s your tightrope. Most operations are still running the same way they did a decade ago:

- Manual entries

- Static reorder points

- One person who “knows how it works”

But what happens when that person’s out sick? Or when the lead time suddenly shifts by 4 days? Or when 2°C is the difference between sellable and spoiled?

You’re not just managing stock anymore — you’re managing survival.

What’s coming will not wait for your spreadsheet.

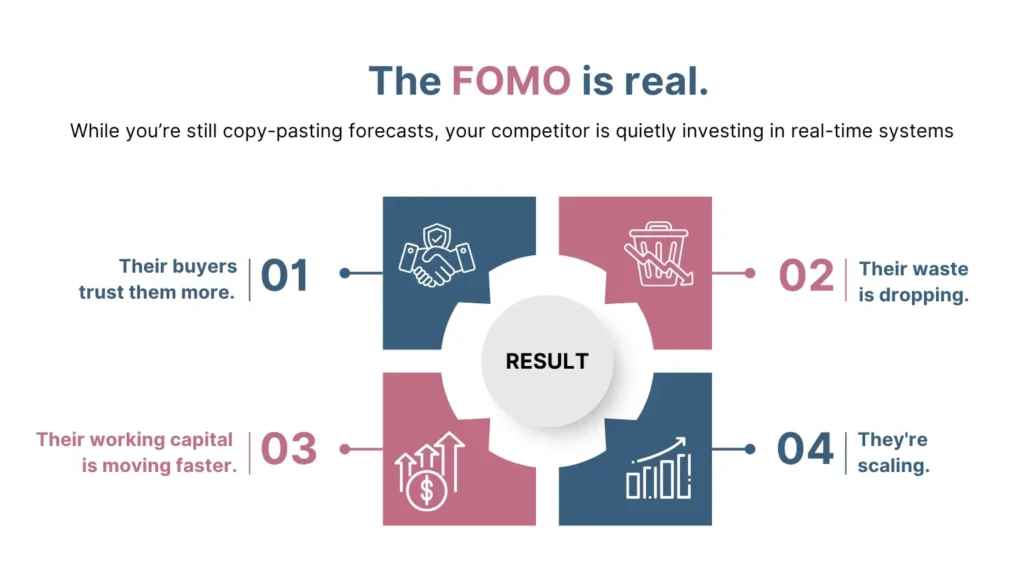

Global food logistics are becoming too complex for “copy-paste” planning. And yet, most brands still:

- Don’t sense demand shifts in real time

- Can’t simulate stockout risks

- Aren’t alerted until something’s already wrong

Let’s say it out loud: Gut feel is not a system. And Excel is not a strategy.

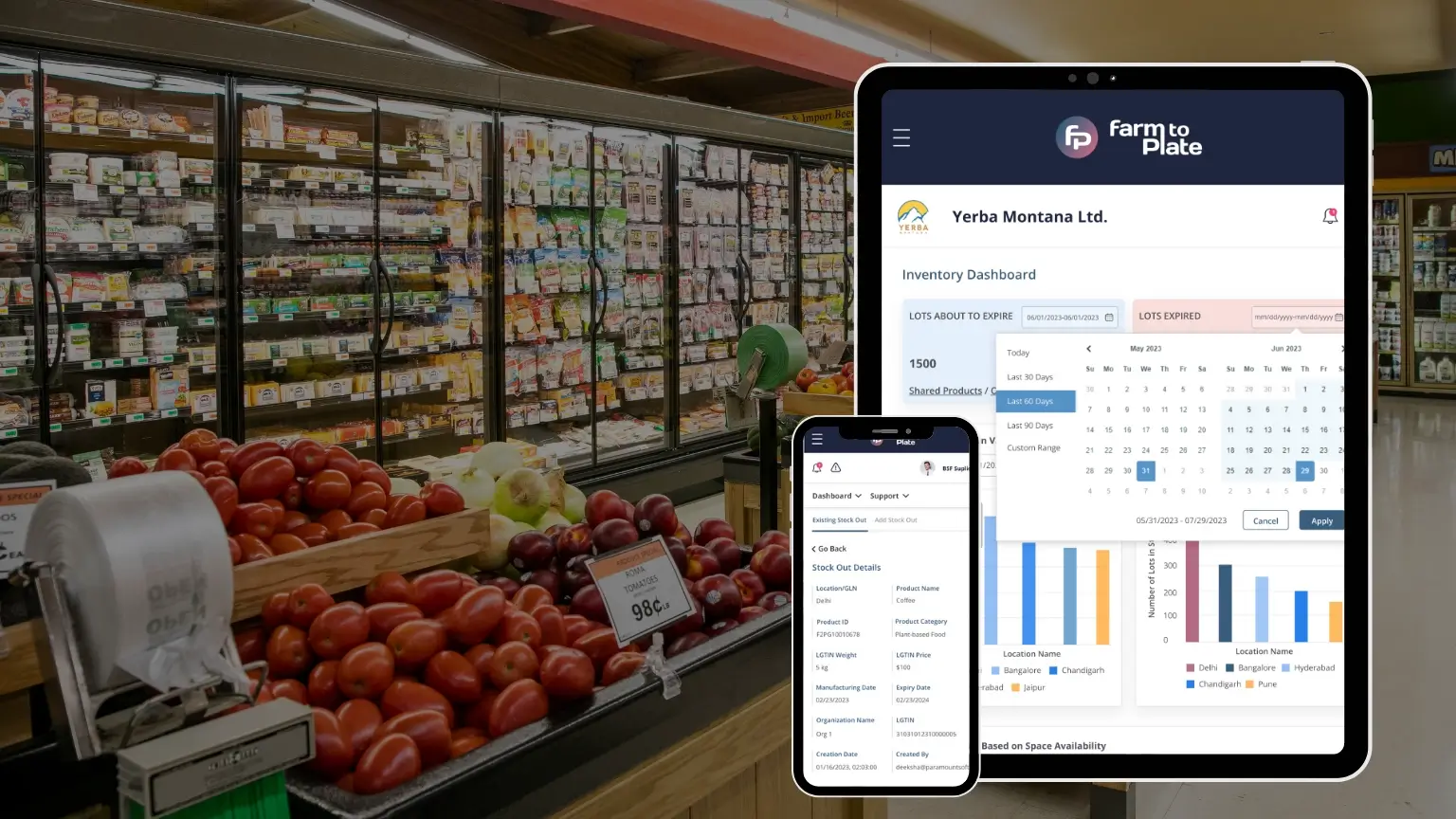

What if your inventory could think?

Imagine a system that didn’t just show you numbers — it warned you.

- “This SKU will likely stock out next Tuesday.”

- “This batch has a 73% risk of spoilage if rerouted.”

- “Your next order needs to shift by 22% to match the trend.”

That’s not sci-fi. That’s smart forecasting, demand sensing, and simulation, powered by modern AI. You don’t need to overhaul everything. Just outgrow the guessing game.

Start with a better way to listen to your data because data doesn’t lie. It tells you where you’re bleeding. And where you can lead.

Let’s be real for a moment.

You’re great at what you do. Your products matter. You don’t need a hundred tools — you need the right one.

Farm To Plate is a platform to support modern food operations — feature by feature.

✔ Use only what you need

✔ No expensive bloatware

✔ Built for ops teams who don’t have time to “figure it out later”

This isn’t a pitch. It’s a reminder: 2025 isn’t waiting. And neither should your inventory.

Curious how your current system stacks up? [Book a free assessment]

This is a blog Series, and next up in the series: How Real-Time Data Powers Smart Inventory Decisions.

✍️Namrata Anand, Senior Technical Content Writer at Paramount Software Solutions & farmtoplate.io