Why AI-driven inventory systems are redefining food supply chains

In a landscape where fresh milk must be delivered before dawn, snack shelves can’t sit empty for an hour, and packaged goods fly off digital and physical shelves alike, replenishment is no longer a background process. For FMCG companies, especially those operating in the food industry, it’s a critical, competitive function.

Yet, many brands still rely on outdated inventory models that can’t keep up with the velocity, variability, and vulnerability of today’s supply chains. As demand becomes more dynamic and consumer expectations more unforgiving, a smarter approach to inventory forecasting and replenishment is no longer optional; it’s essential.

The Challenge: Complexity Meets Fragility

In the world of fast-moving food products, three things dominate operational concerns:

- Perishability–Products often have short shelf lives and must be sold, moved, or transformed quickly.

- Demand Volatility – Consumer behavior is influenced by seasonality, weather, promotions, and even social media trends.

- Fragmented Supply Chains – From sourcing raw materials to distributing across multiple geographies, food brands manage layers of complexity.

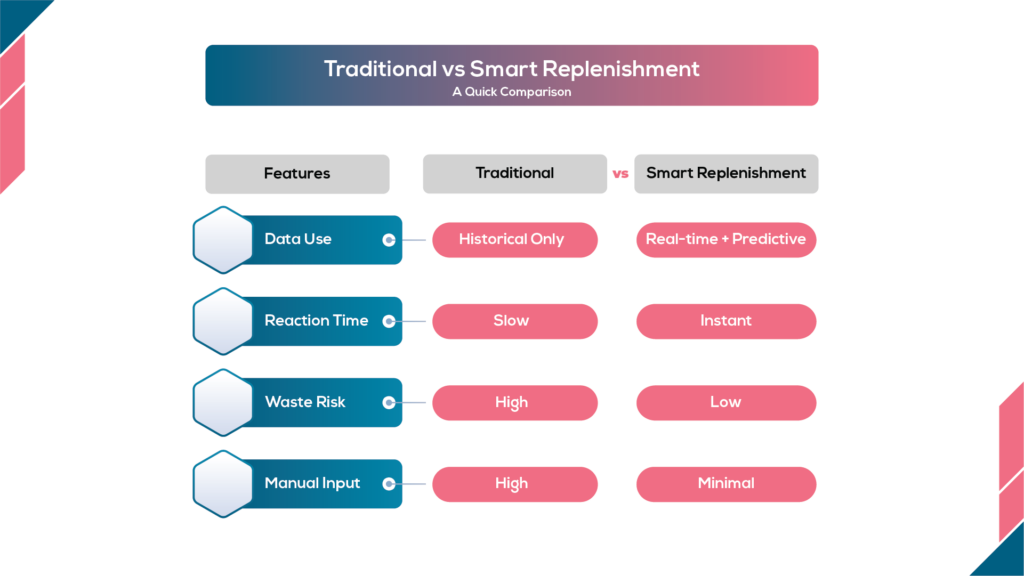

Relying on historical averages or fixed reorder points can’t account for the real-time variables influencing sales and spoilage. These rigid systems often lead to stockouts, excess inventory, or worse, product waste.

Enter Smart Replenishment

Smart replenishment uses advanced forecasting, machine learning, and real-time data integration to adjust inventory flows across the supply chain dynamically. Rather than reacting to demand patterns after the fact, it anticipates them and initiates replenishment decisions proactively.

Real-Time Demand Sensing

Smart replenishment systems continuously collect and process data from:

- Point-of-sale systems

- E-commerce platforms

- Distributor and wholesaler feedback

- External triggers like weather or events

Using this data, algorithms detect subtle demand shifts that traditional systems would miss. For example, a spike in lemonade sales during an unexpected heatwave can trigger replenishment in hours, not days.

Dynamic Forecasting Models

Rather than relying on static rules, modern platforms apply AI models trained to identify:

- Seasonality trends

- Promotion lift effects

- Location-specific demand behaviors

- Shelf-life sensitivity across SKUs

These models generate SKU-level forecasts per outlet, per day, and adapt as new data is received. It’s not just about predicting what will sell—it’s about knowing where, when, and how much to replenish in the most efficient way possible.

Optimized Replenishment Planning

Smart replenishment tools go beyond prediction—they recommend optimal replenishment actions based on business objectives like:

- Reducing waste

- Maintaining high service levels

- Minimizing working capital tied up in stock

- Adapting to vendor constraints and logistics timelines

Automation with Human Oversight

While AI can handle the majority of replenishment logic, it doesn’t exclude humans. Smart systems:

- Automate standard purchase or production orders

- Flag anomalies or exceptions for planners to review

- Offer scenario-based simulations for strategic planning

Why It Works for Food Brands

For food companies, the value of smart replenishment is amplified:

- Reduced spoilage and write-offs from overstocking perishables

- Better shelf availability during peak demand

- Improved visibility across supplier, distributor, and retail nodes

- Enhanced traceability, especially with integrated digital tools

And critically, smart replenishment supports resilience. Whether it’s a sudden surge in demand or a disruption in supply, AI-enabled systems can pivot faster than manual teams ever could.

Results That Matter

Companies implementing smart replenishment systems often report:

- 20–40% reduction in stockouts

- 15–30% drop in excess inventory

- 30–50% improvement in forecast accuracy

- Fewer manual interventions and order errors

These aren’t just operational wins—they directly impact customer satisfaction, brand reputation, and profitability.

Smart Replenishment with Farm To Plate

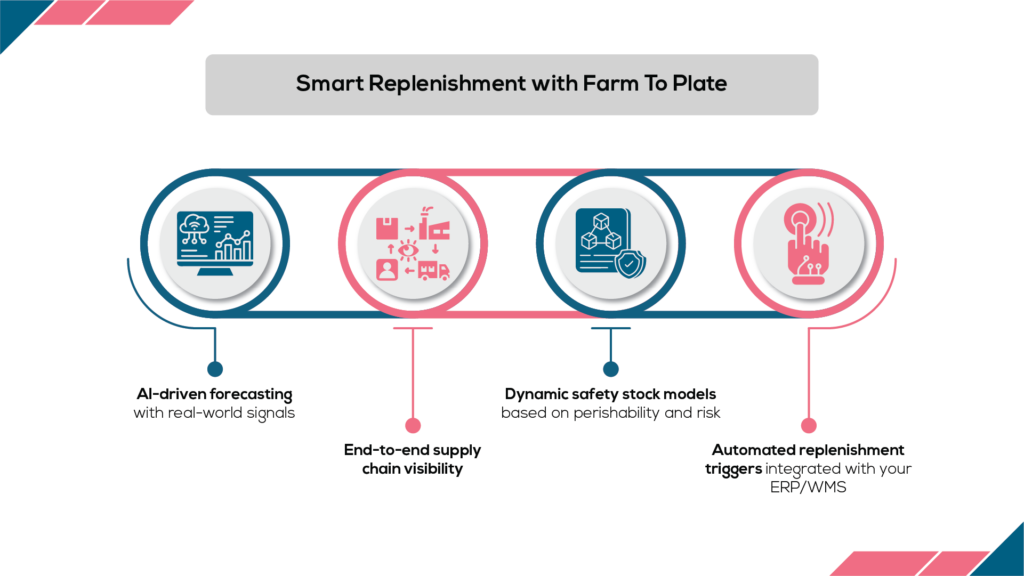

At Farm To Plate, we’ve built our replenishment engine from the ground up for FMCG, with a focus on food production and distribution. Our platform combines:

- AI-driven forecasting with real-world signals

- End-to-end supply chain visibility

- Dynamic safety stock models based on perishability and risk

- Automated replenishment triggers integrated with your ERP/WMS

Final Thought

In the age of instant expectations and real-time commerce, FMCG companies need more than good instincts—they need intelligent systems that think faster, adapt smarter, and replenish precisely.

Smart replenishment is no longer futuristic—it’s a fundamental concept. For food brands, it’s the line between thriving and just surviving.

Written by Sravya Priya, Content Specialist at Farm to Plate. She simplifies complex tech and writes about AI in supply chains, product innovation, and the future of food tech.