Perishable Inventory Control: Spoilage, Expiry & Risk Management

If your spoilage rate is still in double digits, you’re bleeding more than inventory—you’re bleeding profit. The question is: how much of it is preventable?

The question is: how much of it is preventable?

Every year, the food industry loses $400 billion to cold-chain waste—and most of it isn’t because teams don’t care. It’s because processes built for yesterday’s market can’t handle today’s volatility.

- Missed promotions

- Delayed trucks

- Micro-climate shifts

A single storage error can turn thousands of dollars of product into landfill overnight. And if your system only flags risk when expiry is around the corner, you’re already too late.

Here’s the real question:

Do you know your spoilage rate by SKU, location, and lead time—and how much of it is avoidable?

The New Reality: Why Old Controls Don’t Work Anymore

Traditional inventory control was designed for a world where demand patterns were predictable and supply chains were linear. That world doesn’t exist anymore. Today, volatility is the baseline.

Consider this:

- 60% of shrinkage in perishables still comes from preventable factors like delayed alerts and handling errors

- Manual FEFO rotations can increase waste by 10–15% in high-volume environments

- Compliance penalties for missed regulations and reporting add hidden costs

The old playbook static safety stocks, manual checks, and post-event reporting can’t protect your margins in 2025.

Quick Self-Check:

If you answered “no” to any of these, you’re not managing risk; you’re reacting to it.

How AI Changes Perishable Inventory Management

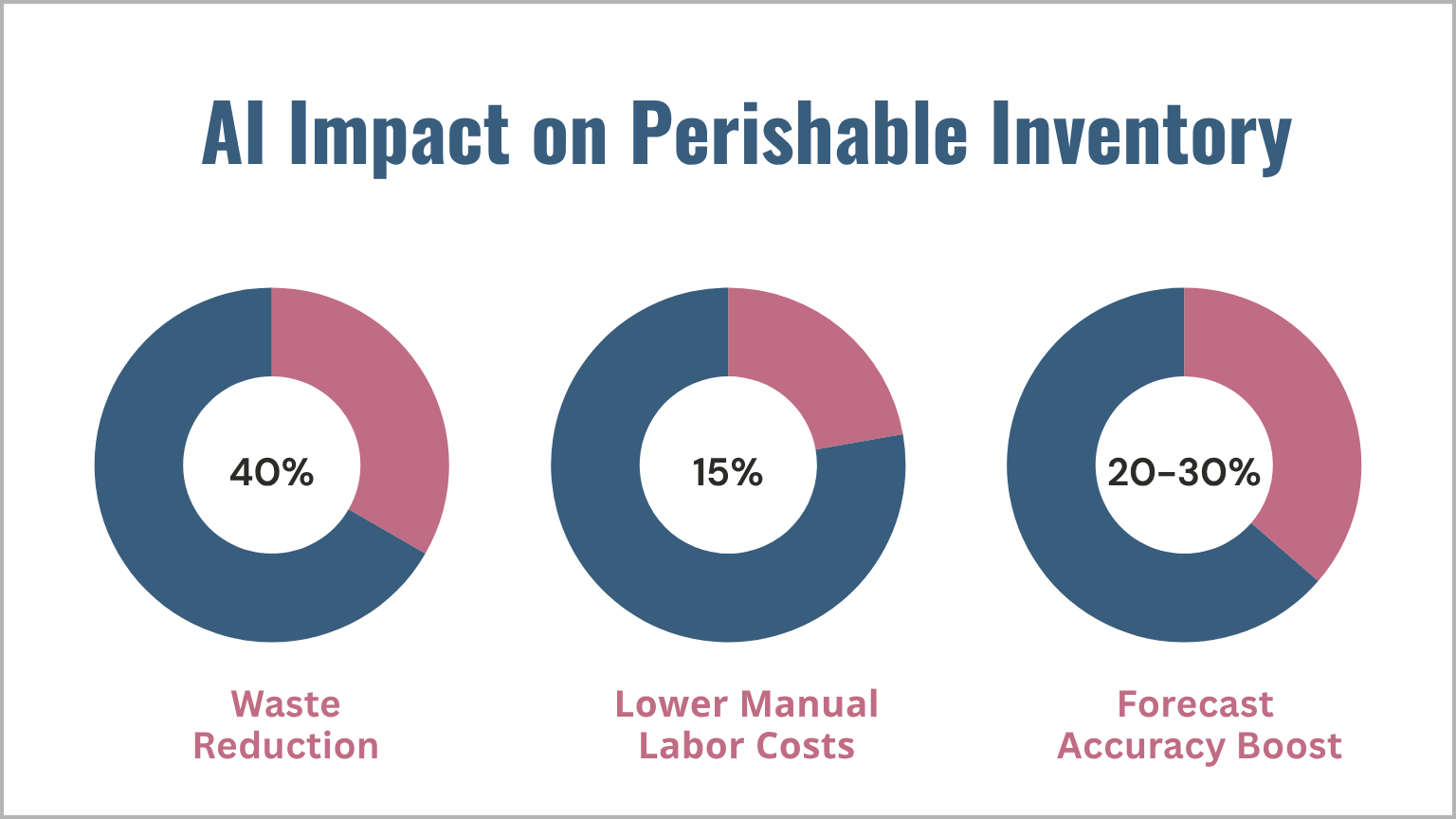

Leaders in F&B are adopting predictive, AI-powered inventory control, and the results speak for themselves:

✔ 20–30% better forecast accuracy with AI-driven demand sensing

✔ 40% waste reduction through shelf-life modeling and smart routing

✔ 25% lower spoilage costs with IoT-driven temperature/humidity alerts

This isn’t theory. This is what keeps major brands competitive and compliant in an unforgiving market.

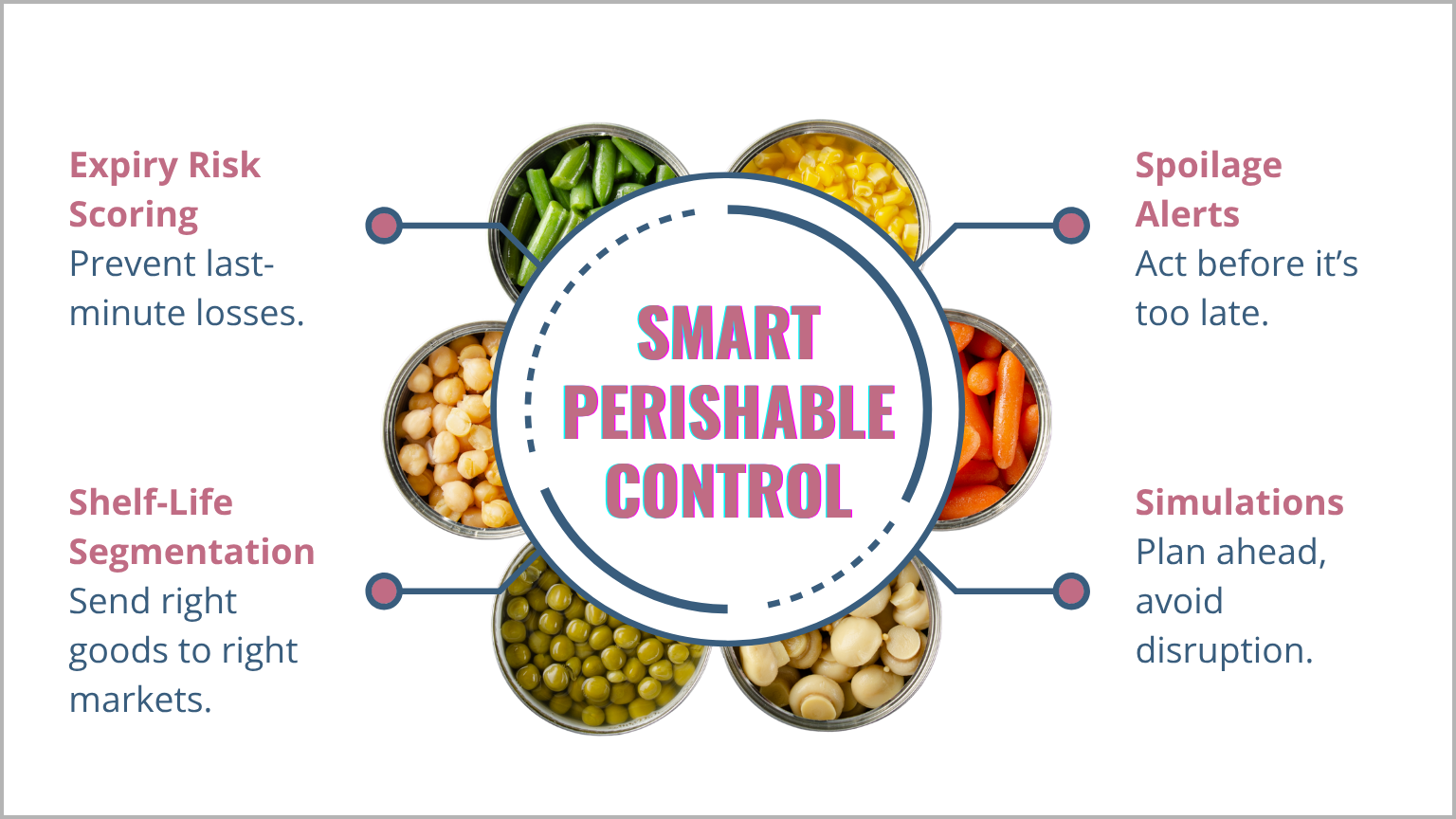

Smart Features That Protect Margins (and Reputation)

Managing perishables isn’t just about counting days; it’s about knowing what happens before the clock runs out. Here’s how advanced tools transform control into confidence:

Expiry Risk Scoring

Not all inventory carries the same risk. Advanced scoring models identify high-risk SKUs early, so you can prioritize allocation and avoid last-minute losses that eat into margins.

Shelf-Life Segmentation

Stop sending near-expiry stock across regions. Intelligent segmentation ensures older stock moves first to local markets, reducing shrinkage while improving customer experience.

Spoilage Alerts That Matter

Forget generic notifications. Smart alerts flag critical deviations, such as temperature drift, humidity spikes, or route delays—so your team can act quickly and prevent waste, not just record it.

Simulation-Driven Loss Avoidance

What happens if a truck is delayed five hours? Advanced simulation answers that instantly—telling you which SKUs are at risk and how to reroute before they expire.

Why This Isn’t Just About Compliance—It’s About Profitability

Compliance is non-negotiable, but if that’s your only goal, you’re missing the bigger picture:

✔ Every 1% in waste reduction can recover up to 3% in margin

✔ Automating FEFO reduces manual labor costs by 15%

✔ Scenario planning slashes emergency freight bills by thousands

Companies still running manual checks and static buffers are not just at risk—they’re leaving money on the table every day.

How Farm To Plate Closes the Gap

If these challenges sound familiar, here’s how Farm To Plate helps you move from reactive to predictive:

- AI-powered shelf-life prediction for SKU × Location × Time

- IoT-driven condition monitoring for real-time temperature and humidity tracking

- Automated FEFO execution integrated with ERP/WMS for zero manual errors

- Blockchain-backed traceability for transparent compliance and audit readiness

This isn’t another dashboard. It’s an intelligence layer for your operations—built to protect margins, reduce waste, and deliver competitive advantage.

How Do You Measure Up?

Ask yourself:

- Is your spoilage rate above 8%?

- Are compliance penalties eating into budgets?

- Do you know the cost impact of a 3-hour cold-chain delay—before it happens?

If you are unsure, don’t stay there. Take the Next step:

Connect with our experts to Request a Free Inventory Health Check or Explore How AI Protects Your Perishables.

What’s Next in This Series?

This is Part 4 of our Advanced Inventory Forecasting & Replenishment series.

Up next: Dynamic Replenishment Planning for Food & Beverage Supply Chains—why fixed-order systems can’t survive 2025 and what adaptive replenishment really looks like.

✍️Namrata Anand, Senior Technical Content Writer at Paramount Software Solutions & farmtoplate.io