A Sweet Deal Turns Sour: What If It Were Your Shipment?

Be honest. What would you do if 15 of your shipments — ready, packed, inspected — were rejected at the U.S. border?

Not because of spoilage. Not due to pesticide residue. But because of a paperwork mismatch.

That’s exactly what happened to Indian exporters this month. 15 mango consignments worth ₹4.28 crore (~$500,000) were destroyed due to one critical form, PPQ203, not aligning with USDA documentation standards.

And here’s the gut punch: The mangoes were fine. It was the paper trail that failed them.

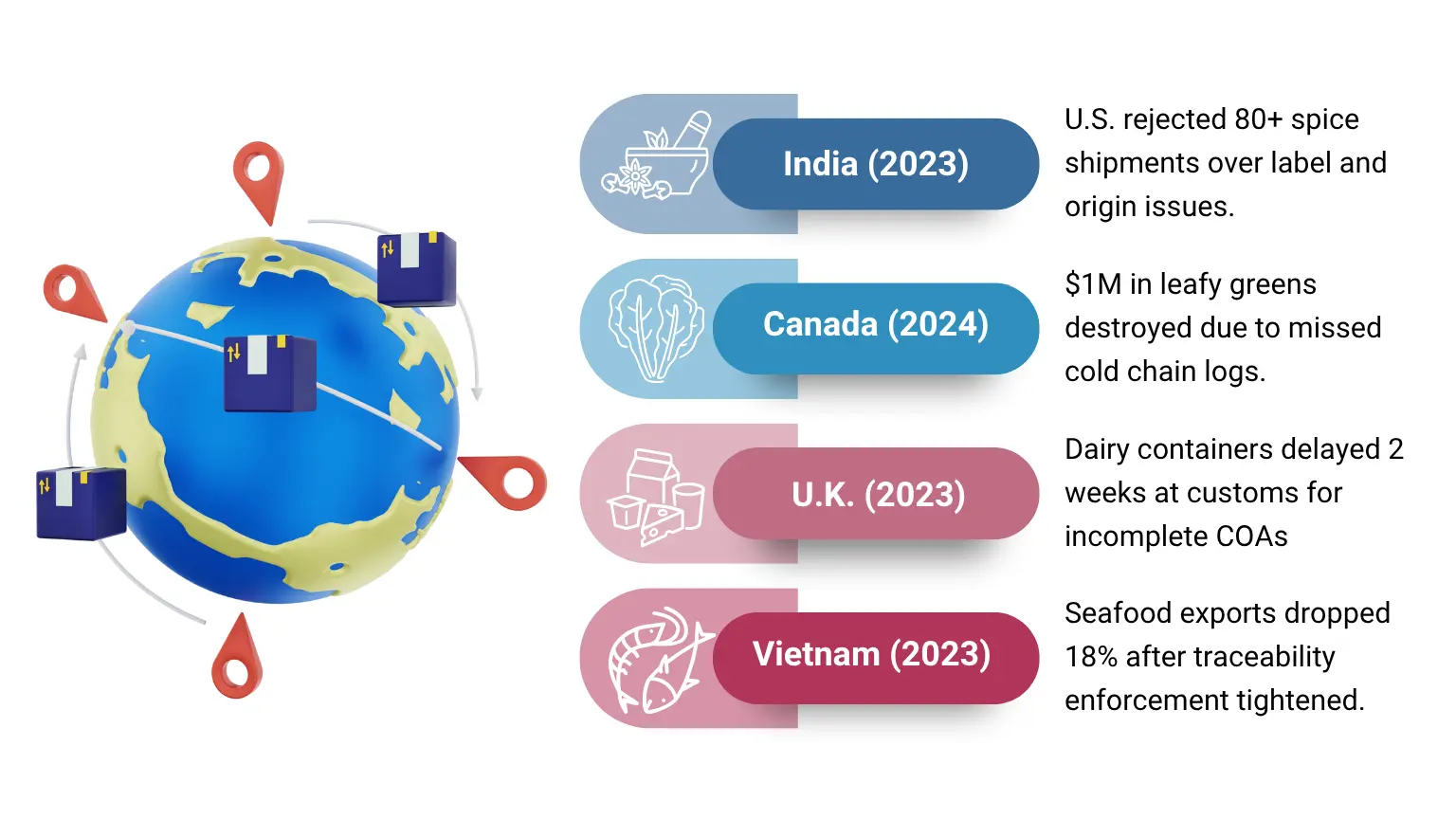

It’s Not an Exception. It’s a Pattern.

You might think, “That’s a one-off.”

It’s not. Across global food supply chains, things are slipping through the cracks.

More than 50% of rejected food shipments globally are due to documentation or traceability gaps, not quality.

Now let’s bring it home: Could your current system catch these issues before your buyer does?

What’s Really Broken? The Way We Track (Or Don’t)

Most businesses still rely on this combo:

- Excel + Email + Hope

- A folder named “Final-Final-Final.docx”

- One person who “knows where everything is”

It may work. Until it doesn’t:

- When an auditor drops by

- When a buyer asks for proof of handling

- When a delay costs you 3% of the deal

And here’s the worst part: You may not even know something’s gone wrong until your product is on a dock halfway across the world, waiting.

How Farm To Plate Helps You Stay One Step Ahead

We are not just another SaaS. We are your compliance co-pilot, visibility tool, and proof of protection — all in one.

Here’s what our customers love most:

Live Traceability & Compliance

- GTIN, LGTIN, SGTIN, GLN, EPCIS: We auto-log every product movement

- FSMA 204(d) & EUDR-ready logs — built for audit-readiness

- Instant recall simulations (takes under 3 minutes)

Smart Documentation Automation

- No more missing PPQ203s, shipping docs, or spec sheets

- Generate buyer-specific files in one click

- Everything is time-stamped, tracked, and securely stored

Cold Chain Monitoring

- GPS + IoT sensors track location, temperature, and more

- Get alerts before deviations become damage

- Full audit trails for every shipment

Shrinkage & Waste Insights

- Catch patterns of spoilage, theft, or improper handling

- Analyze by route, supplier, or product type

Only Pay for What You Need

- Don’t want all the features? You don’t have to.

- Our platform is modular — choose what fits your operation

- Scale with us, as you grow

Curious? Not Sure? Just Ask.

Let’s put aside the buzzwords for a second. If you are scaling your F&B brand, and your backend isn’t evolving, you are risking your hard-earned reputation.

You are good at what you do. You don’t need to be a techie — you just need a partner who’s already solved these problems.

We built Farm To Plate because these issues shouldn’t happen — not to you, not now.

Just clarify. What’s the weak spot in your supply chain?

Is it traceability?

Is it cold chain proof?

Is it documentation?

Let’s find it together — and make sure your next shipment arrives with confidence, not crossed fingers.

We are Farm To Plate. You grow it. You move it. We protect it.

Talk to Us — No Pressure, Just Perspective

✍️Namrata Anand, Senior Technical Content Writer at Paramount Software Solutions & farmtoplate.io